EPS Waste Compactor

TIMO EPS cold compactor with the principle of auger compaction. The operator of the machine puts the used EPS blocks (Styrofoam) into the hopper. The knives inside the machine will shred the EPS foam blocks into smaller flakes. The flakes will be pushed into the compaction chamber and be compressed, while the air inside the material is squeezed out due to the shear breaks the foam bobbles. There is a pressure adjustment device at the end of the compression chamber which can adjust the volume reduction ratio.

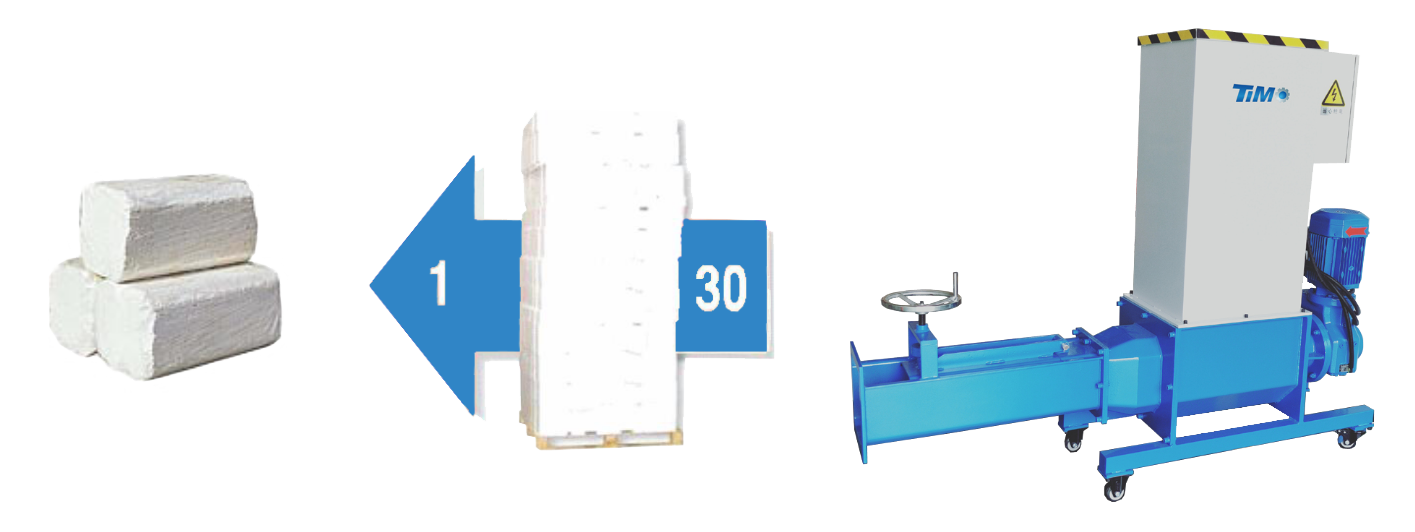

Waste polystyrene compactors are widely used in fish processing plant, electronic factories, supermarkets, and farming. EPS compactors make it profitable for municipalities and businesses to recycle waste polystyrene foam. The light EPS foam scrap is densified to absolute minimum, up to 50 to 1 volume reduction, reaching a densify up to 400kg/m3. With this significant volume reduction, the densified EPS foam will takes up much less storage space, transportation of the logs is cost saving, and residual value of the foam scrap is higher. The machine is energy saving, it generates no odor, and it is convenient for off-and-on operation.

TIMO Waste polystyrene recycling are specifically designed to reduce the size of expanded polystyrene foams for easier storage and transportation. Expanded Polystyrene (EPS) is 98% air, if you are loading up a van and taking your polystyrene to landfill, you are paying your waste contractor to transport 98% air to landfill.

Waste polystyrene is no-biodegradable, no studying can tell how long it takes for EPS to break down, waste EPS product recycling machine can press the EPS into tight blocks and the compacted EPS can be reused, where it is used for different kind of plastic products like picture frames. As a result, the pollution and resource condition will be improved and changed much.

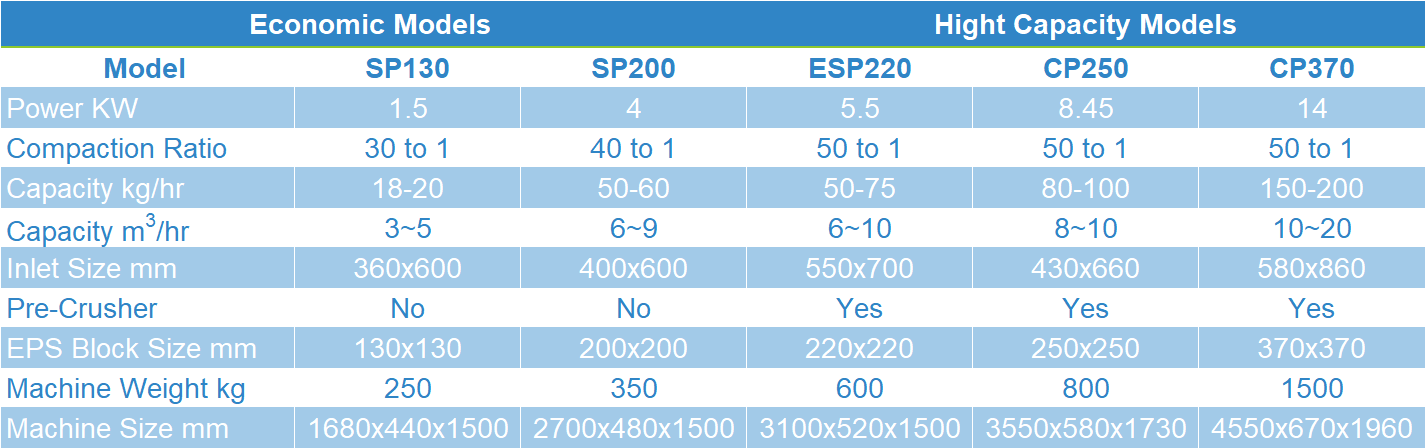

EPS Compactor Technical Data:

How the waste polystyrene Compactor Works

■ You throw EPS scraps into the machine hopper

■ The pre-breaker breaks the foam blocks into smaller flakes

■ An auger compactor presses the foam into compacted logs

■ You stack the logs onto pallets.

■ The result is 7kg/m3 scrap densified up to 400kg/m3

EPS Waste Compactor Feature:

♦ Installed a pre-crusher in the hopper which automatically breaks up larger pieces so you don't have to break them up by hand.

♦ Up to 50:1 compaction. 98% reduction in volume.

♦ Density 300 kg per m³ once compacted (from 10 kg per m³).

♦ Easily loaded by hand or via conveyor for larger installations.

♦ Variable block sizes depending on machine.

♦ Saving handling & transport cost and store space.

♦ Compacted EPS blocks takes-up only 2% to 5% of the original space.