We make 5 types product at present, 1. Industrial Shredder & Dewatering Screw Press (Combination Machine), 2. Industrial Shredders 3. Dewatering Screw Press 4. Small Cabinet-Type Medical Waste Shredder 5. Vertical Hydraulic Baler. Please see introduction as below, and click them you will get more information.

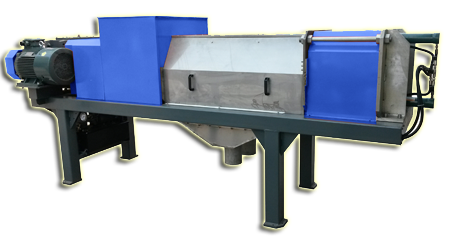

Industrial Shredder & Dewatering Screw Press (Combination Machine)

Industrial Shredder & Dewatering Screw Press (Combination Machine) is the machine that integrate industrial shredder with dewatering screw press. The all in one design for combining size reduction and solid-liquid separtion in one step without conveying. The industrial shredder & dewatering screw press(Combination Machine) can be used in the waste-to-energy application such as refuse-derived fuel (RDF) processing, the waste-to-green application such as biodegradable organic waste composting,the application of commercial liquid food waste processd into biodiesel, and so on. The weight and volume of the waste after treated are greatly reduced and save transport cost.

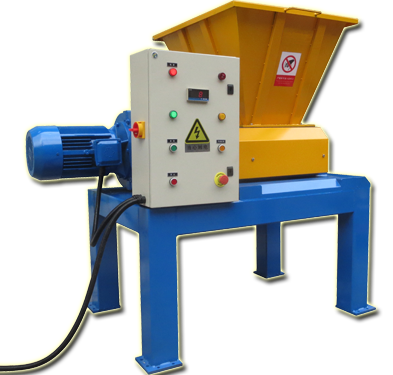

Industrial Shredders

With our broad range of Industrial Shredders we provide the capability to efficiently shred multiple solid waste materials. We build industrial two shaft shredder with single motor or double motors to meet your application requirements. Industrial Two Shaft Shredders is feature of low speed and high torque. The hook shear blades manufactured of high alloy heat treated steel mounted on hexagonal shafts. The number of hooks, reach of hooks, and blades thickness are determined by the material waste being reduced. Our industrial two shaft shredder offer outstanding performance and reliability. These powerful solid waste shredders can handle waste material products including organic waste, kitchen waste, metal, plastic, steel drums, wood pallets, cardboard, and much more. They are specially designed to provide effective operation with low noise, sparking, dust or heat rise.

Dewatering Screw Press

TIMO specializes in the design, engineering and manufacture of Dewatering Screw Presses. These are machines that squeeze liquid out of organic material, operating in a continuous (not batch) mode. Dewatering Screw Press can be used in an extremely wide variety of liquid-solid separation. High-capacity, sanitary press for continuous dewatering and juicing of organic and food products, independently driven rotor and regulated cone section provides instantaneous pressure regulation to give just the right squeeze to the material. We offer small dewatering screw press with diameter Φ240 mm and big model with Φ700 mm in diameter.

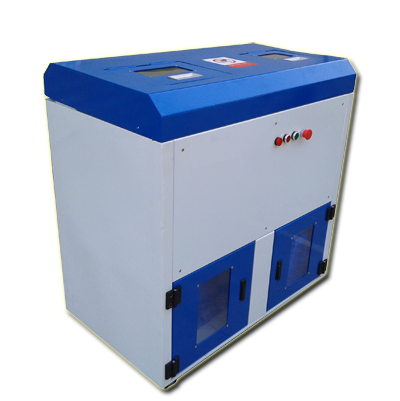

Cabinet-Type Small Medical Waste Shredders

TIMO offers small and compact shredder to process medical waste utilizing the latest shredding technologies. The Cabinet-Type Small Medical Waste Shredders offer a efficient, safe, economical solution for the on-site processing of expired medicine and bio-medical waste such as sharps, dialyzers, syringes, blood bags, plastic and glass. Eliminating the high cost of off-site processing centers can save you thousands of dollars annually. The shredders only take 0.6-0.7 m3 space for working, plug and play, in addition, the shredders mounted on heavy casters for easy mobility. The cabient-type small medical waste shredder equipped with a gravity-feed input chute and high-strength alloy cutting blades that can rotate in two directions to reduce the size and volume of the waste down to 20%, these machines offer impressive performance with minimal noise and vibration. Shredding is important as it enhances the steam penetration therefore improves the overall sterilization results in the next process.

Glass Bottle Waste Crushers

TIMO offers small and compact crusher to process glass bottle waste utilizing the latest shredding technologies. The Glass Bottle Waste Crusher offer a efficient, safe, economical solution for the on-site processing of various glass bottle waste such as beer glass bottle, other beverage glass bottle, medicine glass bottle, infusion bottle, ampoule small glass bottle, penicillin small glass bottle, vaccines small glass bottle etc. The crusher is the ideal hand-fed small glass bottle crusher for small recycling and business applications. Ranging from an under counter crusher for smaller boutique bars, and venues to a larger multi-feed crusher for larger restaurants, hotels and bars with large quantities . The crusher are simple and safe to use, compact design and reliable performance. We have glass bottle crusher model GB400, GB210, GB200, GB220.

Vertical Hydraulic Balers

TIMO Vertical Hydraulic Balers can compress the paper, garbage, cans, film, plastic bottles base on the 5:1 rate,

strapping after compressed reduce a lot of storage space of the waste, easy to transport, reducing processing costs.

• Paper Waste • Domestic Waste

• Plastic Film • Cartons

• Plastic Cans • Bags

• Cloths • Metal

EPS foam compactors

TIMO EPS foam compactors are specifically designed to reduce the size of expanded polystyrene foams for easier storage and transportation.Expanded Polystyrene (EPS) is 98% air, if you are loading up a van and taking your polystyrene to landfill, you are paying your waste contractor to transport 98% air to landfill.

EPS is no-biodegradable, no studying can tell how long it takes for EPS to break down, EPS foam compactor can compact the EPS into tight block and the compacted EPS foam can be reused, where it is used for different kind of plastic products like picture frames. As a result, the pollution and resource condition will be improved and changed much.