TIMO offer large capacity food/organic/kitchen waste composting system up to 7-10 tons/hr. The system is suitable for processing the supermarkets leftovers, food factories remains, door to door organic waste, expired food waste with package etc. The system is composed of 3 systems which is bag breaker system, self propelled compost turner machine, trommel screen system. After processing, the food/organic/kitchen waste will be convert to fertilizer, and the inorganic waste such as plastic bag, plastic bottle, stone, cardboard box etc will be separated. The introduction of the system is as below.

Processing Flow:

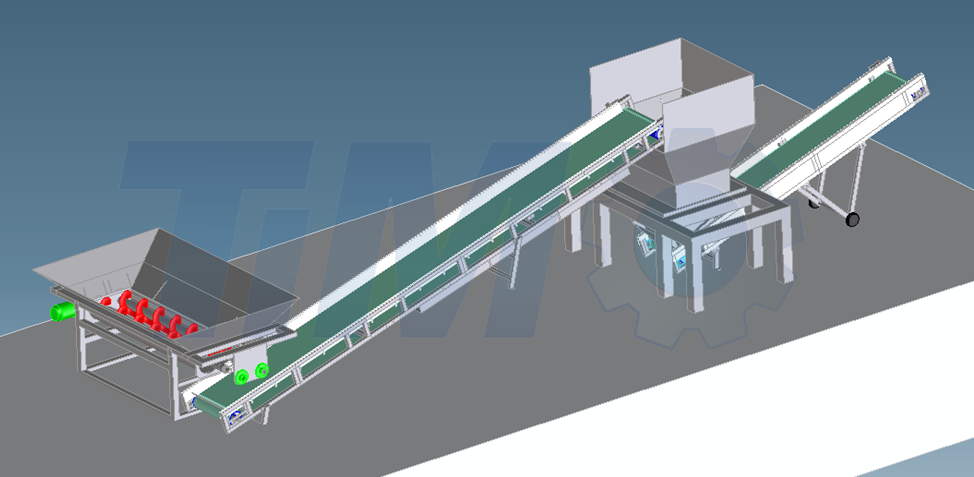

Stage 1 (Bag Breaking) : 1)SUS304 Automatic storing & feeding hopper–>2)SUS304 chain plate conveyor(Feeding)–>3)Bag breaker (Cutting packing bag)–>4)SUS304 chain plate conveyor (Discharging)

Stage 2 (Aerobic Composting): Do natural aerobic composting with self propelled compost turner, the compost turner has automatic liquid spraying device to add microbial strain, the food/organic/kitchen waste will become loosen and dry fertilizer.

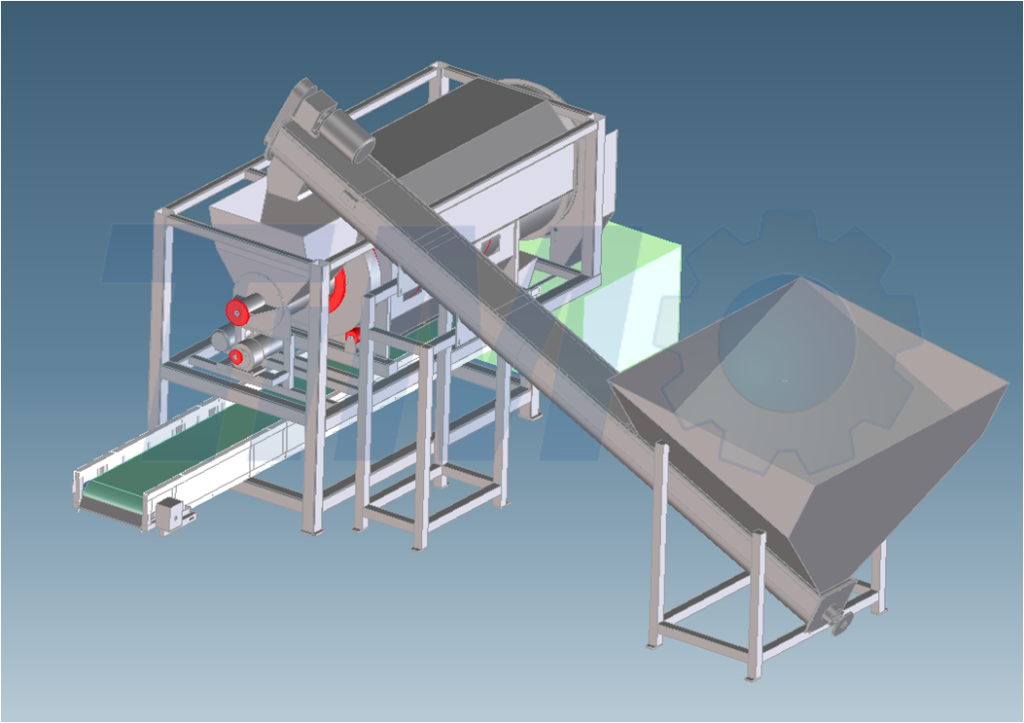

Stage 3 (Fertilizer & Package Separating): 1) SUS304 Single auger conveyor with big hopper(Storing & feeding)–>2)Compost Trommel screen–>3)Horizontal SUS304 chain plate conveyor (Dicharging Fertilizer).

The working principle is as follow: 1. The loader take the food/organic/kitchen waste and pour them to the automatic storing & feeding hopper directly, there are two screws in the bottom of the big hopper, the two screws will push the waste to the next chain plate conveyor–>2. The chain plate conveyor will convey the waste to the bag breaker–>3. The bag breaker will tear and shear the bags but not damaging content inside, and the waste will fall off to the next conveyor–>4. The discharging conveyor will convey the food/organic/kitchen waste to the ground. The food/organic/kitchen waste which mixed with the package will be done composting in the ground. After the waste become the loosen and dry fertilizer, then come to the trommer screen system–>5. Put the fertilizer to the big hopper of the single auger conveyor, the conveyor will convey the fertilizer to the trommel screen–>6. The trommel screen do clockwise rotation, there are screen and guide rail in the rotating drum, the dry and loosen fertilizer will pass through the screen and fall off to the horizontal conveyor–>7. The horizontal conveyor will discharge the fertilizer to the ground. At the same time, the big foreign objects such as plastic bag, bottle, stone, cardboard box will be discharged along with the guide rail in the other side outlet. Finally, the organic waste which mixed in the solid waste will become fertilizer, and the fertilizer and the solid waste will be separated too.

Bag Breaker System

The bag breaker system provide the capability to efficiently opens bags at high volumes without damaging content, ensuring maximum recovery of valuable recyclables. The Bag Breaker uses large, counter-rotating drums to efficiently open the bags and release the contents, discharging them from the bottom of the machine. Bags are torn into large pieces for easy removal. Bagged food/organic/kithcen material will be fed directly into the Bag Breaker with the chain-plate conveyor to achieve an evenly-metered flow rate. We build double shaft bag breaker with double motors to driven independent cutting shaft. The auxiliary shaft runns in low speed than the main shaft, this will creat tear and shear effect to break the bags but not damaging content inside. The high capacity bag breaker can handle waste material products including municipal solid waste (fraction up to 300-400 mm), organic waste, mixed materials in bags. The 3D picture below to show you how the bag breaker system looks like:

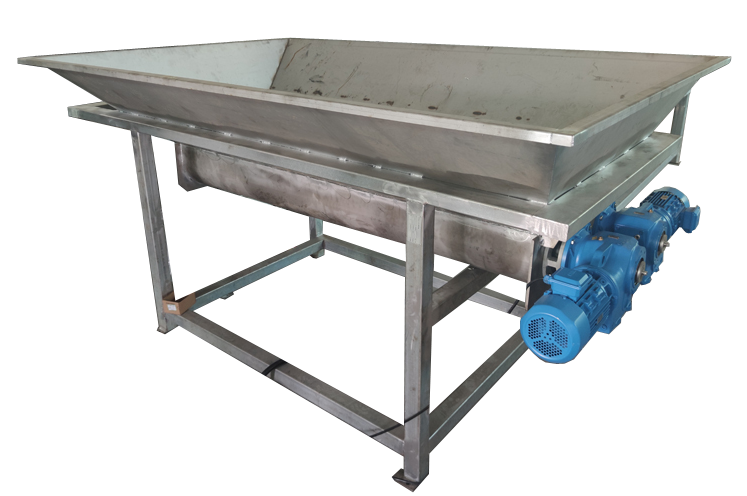

Automatic Storing & Feeding Hopper

There are two screws in the bottom of the big hopper, the two screws will push the waste to the next chain plate conveyor.

SUS304 Chain Plate Conveyor

The chain plate conveyor is made of solid stainless steel, no rusty, long life span. Feeding the waste to bag breaker.

Bag Breaker

Efficiently opens bags at high volumes without damaging content, ensuring maximum recovery of valuable recyclables.

Discharging Conveyor

Connecting to the bag breaker, discharging the depacked waste to the ground, discharging height 1.6 meter but can be customized made.

Aerobic Composting By Compost Turner

The mixed food/organic/kitchen waste should do composting on the ground by a self-propelled compost turner assistant, seft-propelled means that the compost turners have four wheels, which allows them to move freely. The main function of the compost turners, which are also known as windrow turners, is to create compost for use as fertilizer. In the past, traditional composting methods had issues with environmental pollution, long-term contamination, and killing good microorganisms. So the key component to producing high-quality fertilizer is adding microbial strains and oxygen to food/organic/kitchen waste and other solid waste. Using a self-propelled composting turner(windrow turner), you can lower the temperature of the compost and fill the mix with oxygen. And the compost turner should have an automatic liquid spraying device to add microbial strains when turnning. This method prevents poisonous gasses from accumulating and meets the requirements of the Environmental Protection Act. The main function of a self-propelled compost turner is to turn original pollutants turn into organic fertilizer, this is ideal for the soil because it can absorb the compost and kill germs easily. A self-propelled compost turner accomplishes its job faster with a higher success rate than other machines. They have a larger production capacity and added space to complete the composting process. The picture of the self-propelled compost turner attach below for your reference.

Trommel Screen System

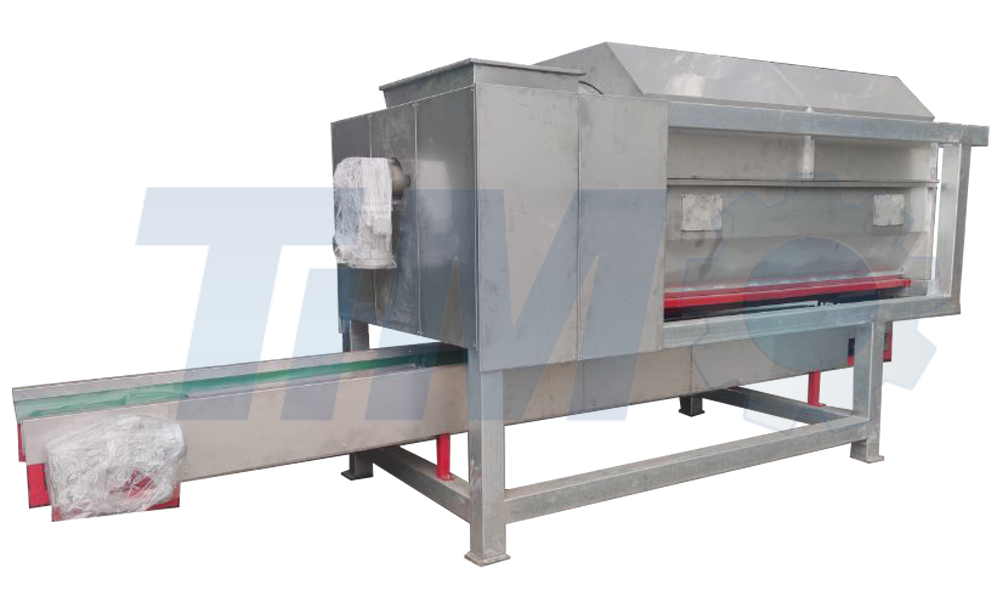

TIMO compost trommel screen has adopted the latest technology to make the trommel more environmental-friendly, energy-saving and economical. Our trommel screen consist of a perforated cylindrical drum, electrical motor, reducation gearbox, screen frame. sealing cover etc. The drum will lifted up the material waste by rotation as they fall back down, this action will repeated with each revolution along the length of the drum. There are material spiral guide rail install inside the drum, when material waste flow towards along the spairal guide rail in the rotating drum, material jump and roll,the undersized material smaller than the screen apertures passes through the screen, while the oversized material exits along with the spiral guide rail at the other end of the drum. Trommel screen has wide range of sizes and capacity from 5-50 tons/hr, trommel screen is a mechanical screening machine used to separate different size material.

Features And Application:

♦ Customized made designed – Trommel screen can be customized to meet different capacity and working site.

♦ Environmental-friendly – Fully enclosed structure, no dust pollution, improve working conditions for operators as well.

♦ Variable application range – compost, organic waste, green waste, wood waste (bark, sawdust, woodchips etc), domestic refuse, municipal waste, stone and many other material.

♦ Superior design – Simple structure, easy maintenance, steady operation, low energy consumption.

♦ Screen long life span – Screen is made of solid stainless steel SUS304 with strong strength, good abrasion resistance, no rusty and high screening efficiency.

The 3D picture below to show you how the trommel screen system looks like:

SUS304 Storing & feeding auger conveyor

Single auger conveyor can store over 5 m3 waste, the loader can put the waste directly here. The hopper volume can be customized made.

Compost Trommel Screen

Trommel screen is a mechanical screening machine used to separate different size material with wide range of sizes and capacity from 5-50 tons/hr.

Outlet of Inorganic Waste

The oversized material such as plastic bag, plastic bottle, stone etc. exit along with the spiral guide rail at the other end of the drum.

Horizontal Discharging Conveyor

The undersized material smaller than the screen apertures passes through the screen and discharging by the horizontal conveyor.