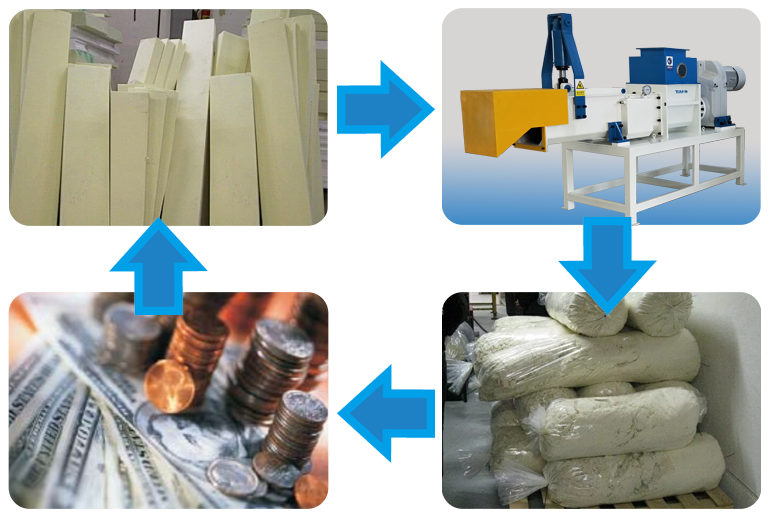

PUR (Polyurethane) Foam Waste Compactor

In general, recycled PUR foam materials come from the fast consumer goods, such as: daily necessities, automobile, mattress, carpet padding and backing and id equipped with soft cushion of the sofa, insulation material for walls and panels in industrial buildings and cold stores. Polyurethane (PUR) foam waste recycling has become more and more important, especially in Europe, the place to dispose of the rubbish becomes less and less. And waste disposal costs are also rising crazily. As the government of polyurethane products production cycle improvement of production, there is much innovative recycling technology in.

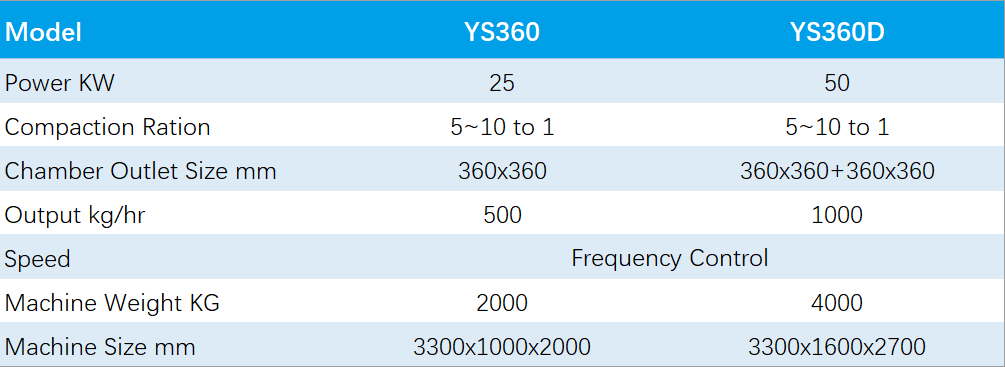

TIMO PUR Foam Waste Compactor

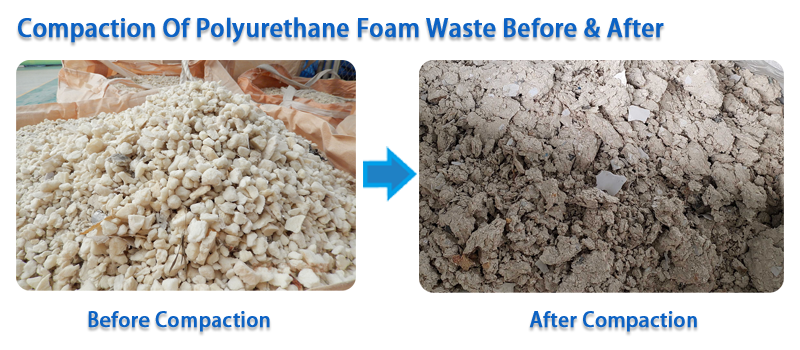

TIMO screw compactor YS360 can break and compact PUR foam waste into a cylinder shaped block with a density of 320-350 kg/m³. The compacted material can go to PUR foam waste recycling and instead of ending as waste on landfill it can now be recycled into new products.

The PUR foam waste can be compacted directly into endless plastic bags. Thereby the poisonous PUR dust is also incapsulated and sent to PUR recycling centers.

The pre-crusher is an optional installed part for crushing the whole PUR foam plates into pieces, and the PUR foam pieces can be feed into the hopper directly, and the screw and hydraulic jaws compact the material. At recycling centers for refrigerators and freezers the YS360 can be installed directly under a silo for collected PUR foam pieces. From PUR-production the dust can be absorbed via a vacuum system and then blown to the compactor via a silo system with cell lock.

How the PUR Compactor Works

■ You throw PUR foam waste into the machine hopper

■ The PUR foam sheet need a pre-crusher to breaks them into small pieces, we can install the pre-crusher, it is an optional item, because small pieces PUR can be feed into the screw compactor directly.

■ An screw compactor presses the foam into compacted flakes

■ The PUR foam waste can be compacted directly into endless plastic bags.

■ The result is 7kg/m³ waste densified up to 70kg/m³

PUR Foam Waste Compactor Feature:

■ Compaction ratio 5~10 to 1.

■ Screw compaction principal: Safe and operate.

■ Customization for options of special feeding hopper.

■ Small footprint, energy saving.

■ Compacted foam will not bounce back.

■ Match with German technology production line.

■ Compact PUR without risk of explosion as the gas constantly is sucked away during the process.

PUR Compactor Case Show: