Food Waste Depackaging Systems

Food Waste Depackaging Machine

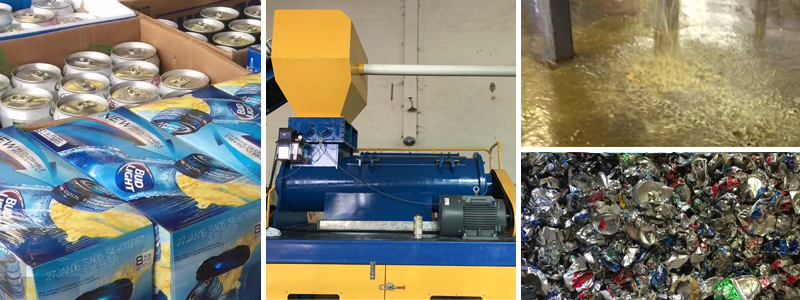

Food waste depackager is a good options on separating the food waste, organic waste, or source separated organics(SSO) from the heterogeneous feedstock, this separation process has one input, the heterogeneous feedstock, and two outputs, the extract (the recovered material, e.g. food scraps, organics) and the reject (e.g. waste packaging). The separated food/ogranics are taken as the raw material to do composting, or convert to the biogas by wet anaerobic digestion.

TIMO offer food waste depackaging system to separate packaging with the least amount of applied force necessary to avoid splintering of the packaging, the system can accept the mixed furits & vegetable waste, mixed supermarket waste, packaged produce, restaurant waste, expired daily food waste, etc., with all their packaging, for examples, separating organics from beverage cartons and cans, canned foods, wrappers, bags, styrofoam, yogurt, plastic bottles or plastic jar packaging, aluminum foil, cardboard, etc., Food waste depackagers operate in the 90 to 97 percent recovery and purity range, depending on how much food remains adhered to the packaging after separation.

Types of food waste accepted by TIMO:

Beverage Cartons

Canned food

Mixed Supermarket Waste

Bakery Waste

Kerbside Waste

Restaurant Waste

Food waste processing: One input, Two oupts

♦ Solid Food Waste:

From mixed organic waste

To clean organic flow

To various packaging waste

♦ Liquid Food Waste:

From various beverage waste

To clean beverages(Coca-Cola, water, etc)

To various packaging plastic bottle

Feature of Food Waste Depackaging Machine:

- Robust and compact construction, customized made hopper and base for working site.

- Larger screen surface in the drum sections to maximize throughput capacity.

- Wear-resistant, highly stressed and long life-span separating paddle.

- Various screens size for optional depending on product, capacity, and separation quality demands.

- Option to inject water(spray nozzles) into the depackaging chamber for sticky solids.

Applications For food waste depackager:

- To prepare organics substrate for wet anaerobic digestion.

- To prepare organics for composting plants.

- Keep contaminants out of the feedstocks for a wet anaerobic digester system and out of compost-based finished product(s).

- Reduce contamination removal costs in the composting facilities as well as reduce the tipping fee for industrial food product depackaging and recycling.

- Pre-consumer, packaged food waste in all forms (except glass containers)

- Post-consumer, mixed source separated organics (SSO) from restaurants/hotel, supermarket, farm, factory rejects and other food co-products.